- Home

- Laser Welding

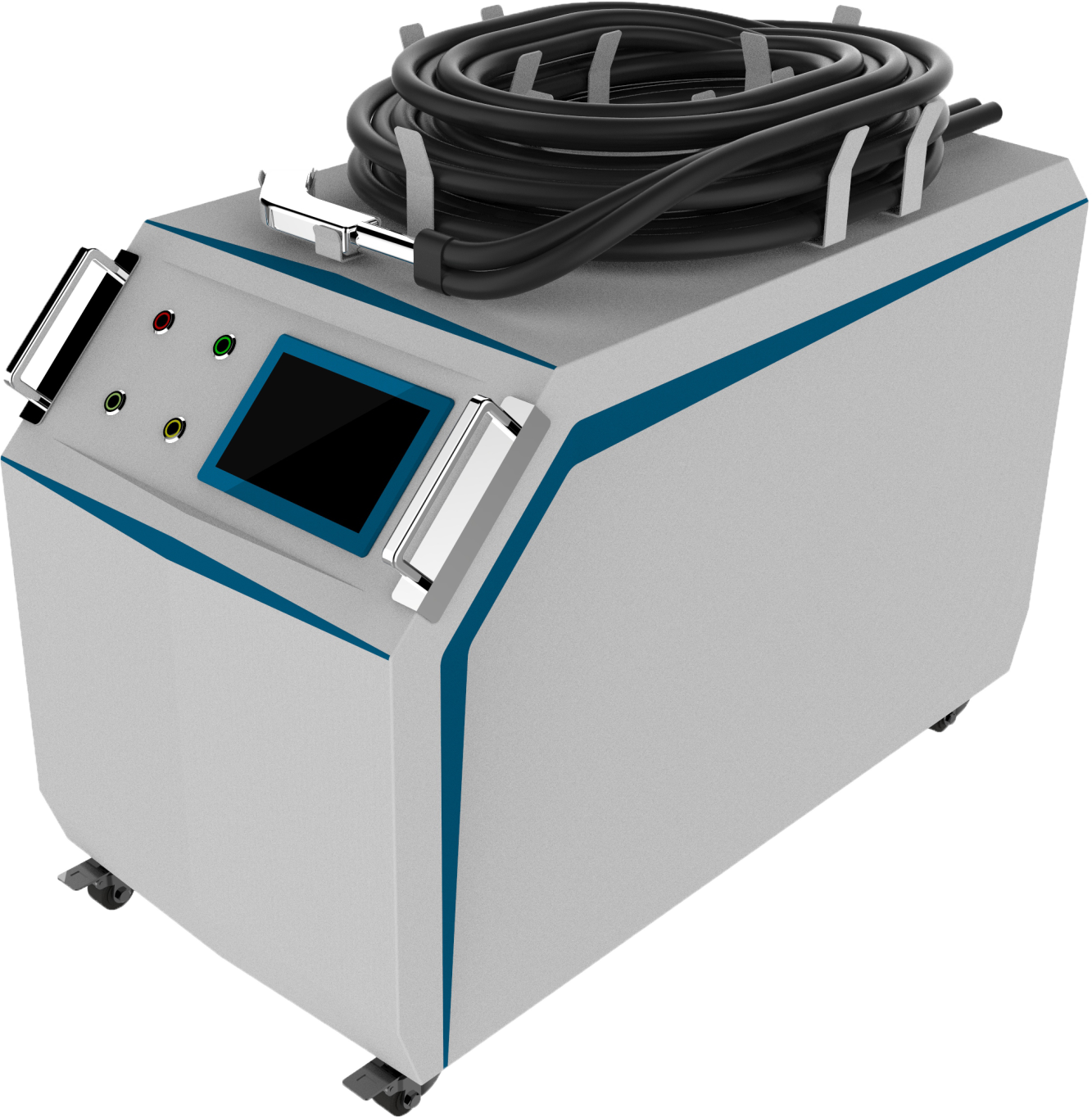

- Laser Welding

Laser Welding

Laser Welding uses a highly concentrated beam of light on a very tiny spot so that the area under the laser beam absorbs the light and becomes highly energetic. As powerful laser beams are used, the electrons in the area get excited to a point where the material melts as the result of the atoms breaking the bonds with each other.

- Laser welding offers a high level of accuracy and control without causing any damage to the part.

- It is capable of handling complicated joins.

- Using Laser welding technology you can weld dissimilar materials, as well as areas which would be too difficult to reach using traditional welding techniques.

- Low heat application minimizing distortion of the components

- Contact-free application which results in less thermal strain being placed on the parts

- Consistent and repeatable welds

- Make high strength welds and there is no need for a filler material to be used

- Deep penetration welding in addition to increased productivity, laser can weld thick metal in a single pass.

- Simplified part designs resulting in stronger components, which can be produced at lower cost.

Lasers provide excellent weld quality and clean processing, which is why it is favoured by manufacturers. Laser Beam welding is used for high precision welds. Since it doesn’t employ any electrode, the final weld will be light but strong.

Samples